When it comes to product presentation, durability is often as important as design. A label is not just a decorative element. It communicates your brand identity, provides important product information, and helps set your items apart in a competitive marketplace.

While there are many labeling options available today, screen printed labels have earned a reputation for being among the most resilient and dependable. Businesses in industries ranging from apparel to outdoor equipment rely on them because they can withstand the test of time and maintain their bold, professional appearance.

What Are Screen Printed Labels?

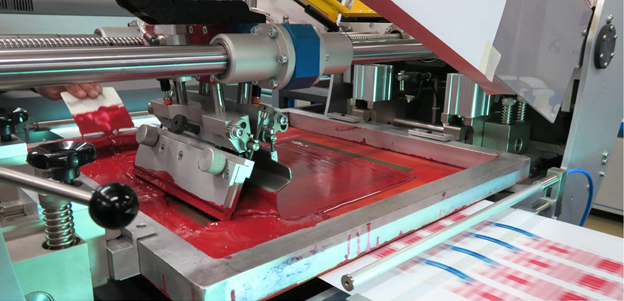

Screen printed labels are made using a traditional printing technique known as screen printing. This method involves pushing ink through a mesh stencil (or screen) directly onto the label material. Each color is applied separately, which makes the process meticulous but also highly customizable. Unlike digital or thermal printing, screen printing creates thick, vibrant layers of ink that adhere firmly to the surface.

Because of the way the ink is deposited, the final result is not only bold and sharp but also highly resistant to wear. These labels can be applied to a wide range of materials including fabric, plastics, and metals, making them a versatile choice for many industries.

Why Durability Matters in Labels

A label is more than a temporary tag. For many products, the label needs to last as long as the item itself. Imagine purchasing a jacket where the care instructions fade after a single wash or buying industrial equipment where the safety information label peels off after a few months of use. These situations not only frustrate consumers but can also create compliance and safety concerns for businesses.

Durability in labels ensures that branding, instructions, warnings, or certification marks remain legible throughout the lifespan of the product. Screen printed labels meet this challenge head-on, giving businesses peace of mind that their messaging will remain intact under demanding conditions.

The Durability Advantage of Screen Printing

The durability of screen printed labels comes from several key factors that set them apart from alternatives:

1. Thicker Ink Layers

Screen printing applies ink in thicker layers compared to most other printing methods. This extra density makes the ink less prone to fading or rubbing off, even with repeated handling or exposure to rough conditions.

2. UV Resistance

One of the greatest threats to printed labels is ultraviolet light from the sun. Many digital or thermal printed labels fade quickly when exposed to sunlight. Screen printed inks, on the other hand, are often UV resistant, allowing labels to maintain their vibrancy and legibility for years, even in outdoor environments.

3. Abrasion Resistance

Labels on products that are handled frequently or exposed to friction must be able to resist scratches and wear. Screen printing produces durable surfaces that stand up well against abrasion, which is one reason why these labels are commonly used in heavy-duty industries like manufacturing and automotive.

4. Chemical and Moisture Resistance

Products exposed to cleaning agents, oils, or moisture need labels that can handle these elements without peeling or smudging. Screen printed labels, particularly when sealed with protective coatings, can endure exposure to many harsh chemicals and remain intact.

5. Heat Resistance

In certain industries, labels must remain stable at higher temperatures. Screen printed labels can be engineered with inks and substrates that resist heat, making them reliable in demanding settings like electronics or automotive manufacturing.

Industries That Depend on Durable Labels

Durable screen printed labels are not a niche solution. They are essential for many industries where reliability is non-negotiable.

Apparel and Textiles

Screen printed labels are widely used in clothing, hats, and bags. Unlike fabric tags that can fray or peel, screen printed labels remain vibrant and comfortable against the skin. They also last through countless washes without fading.

Industrial Equipment

Machines and tools require safety labels and instructional markings that remain visible for years. Screen printed labels are ideal because they resist oil, dirt, and abrasion, making them reliable in rugged work environments.

Outdoor Gear and Sporting Goods

Labels on tents, backpacks, or sports equipment must withstand sun, rain, and frequent use. Screen printing ensures that brand logos and product details remain clear in these tough conditions.

Electronics

Electronic devices often include warning labels, serial numbers, and compliance certifications. Screen printed labels are chosen because they resist heat and abrasion, which helps them endure years of use.

Consumer Goods

Everyday products, from water bottles to kitchen tools, often carry logos and instructions that must last the life of the product. Screen printed labels ensure that the brand identity stays strong even after prolonged use.

Comparing Screen Printed Labels to Other Options

To understand why screen printed labels excel in durability, it helps to compare them to alternatives:

- Digital Printing: While cost-effective and fast, digital prints often lack the ink thickness and UV resistance of screen printing, making them more prone to fading.

- Thermal Transfer Printing: Common for barcodes and small text, this method works well for short-term use but is not designed for the same longevity as screen printing.

- Paper Labels: While inexpensive, paper labels are highly vulnerable to tearing, moisture, and fading, making them unsuitable for long-term or outdoor use.

Screen printed labels may cost more upfront, but the long-term benefits outweigh the initial expense, especially when durability is essential.

How Businesses Benefit from Long-Lasting Labels

For businesses, investing in screen printed labels goes beyond aesthetics. It is a practical decision with multiple advantages:

- Reduced Replacement Costs: Durable labels minimize the need for re-labeling products or replacing damaged tags.

- Compliance Assurance: In industries with regulatory labeling requirements, long-lasting labels ensure consistent compliance.

- Stronger Brand Identity: Labels that stay bold and clear reinforce brand trust and recognition over time.

- Improved Customer Experience: Customers appreciate when product information remains legible, especially in clothing care or equipment usage.

Durability in labels is not something businesses can overlook. Whether it is a clothing brand that wants its labels to survive hundreds of washes or an equipment manufacturer that needs safety information to remain clear for years, screen printed labels are a trusted solution. Their thicker ink layers, resistance to UV light, abrasion, chemicals, and heat make them one of the most reliable labeling methods available today.

While other printing techniques may offer speed or lower initial costs, the longevity and resilience of screen printed labels ensure that they provide lasting value. For businesses that prioritize brand integrity and product reliability, screen printed labels are truly built to last.

The information below is required for social login

Sign In

Create New Account